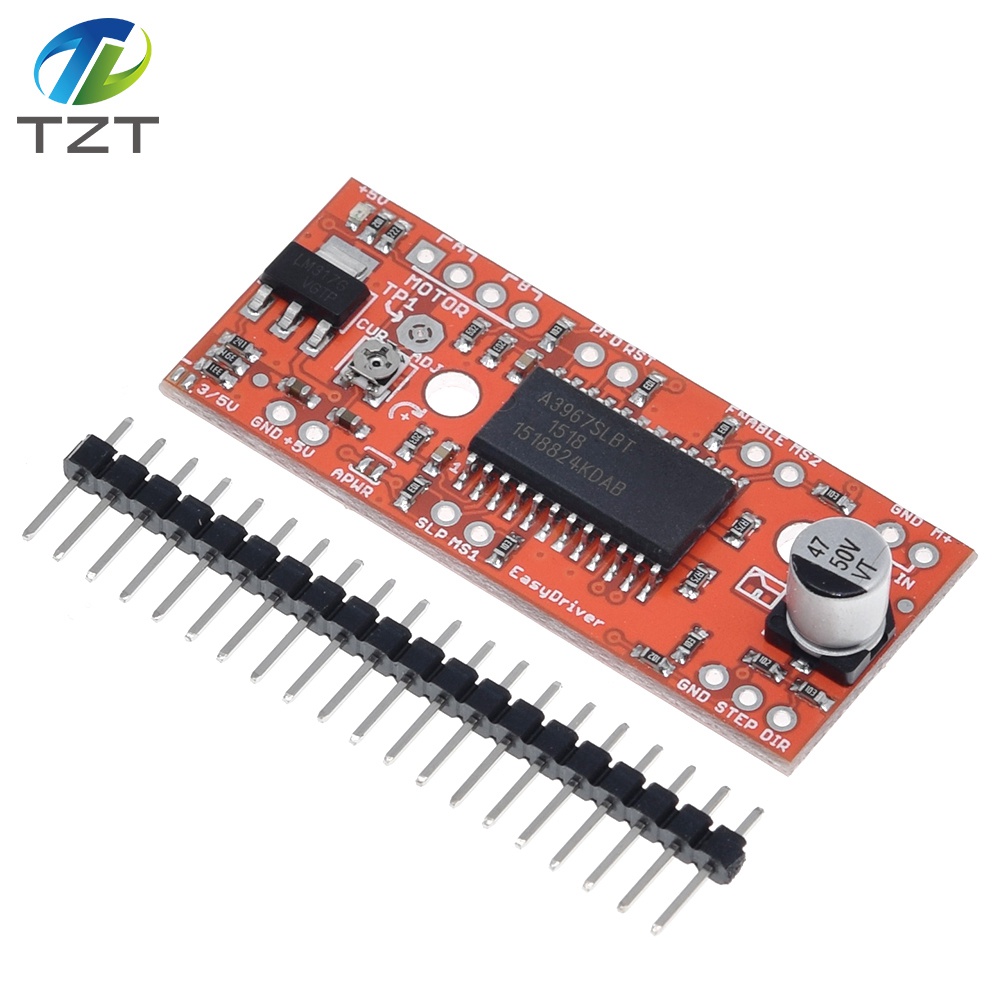

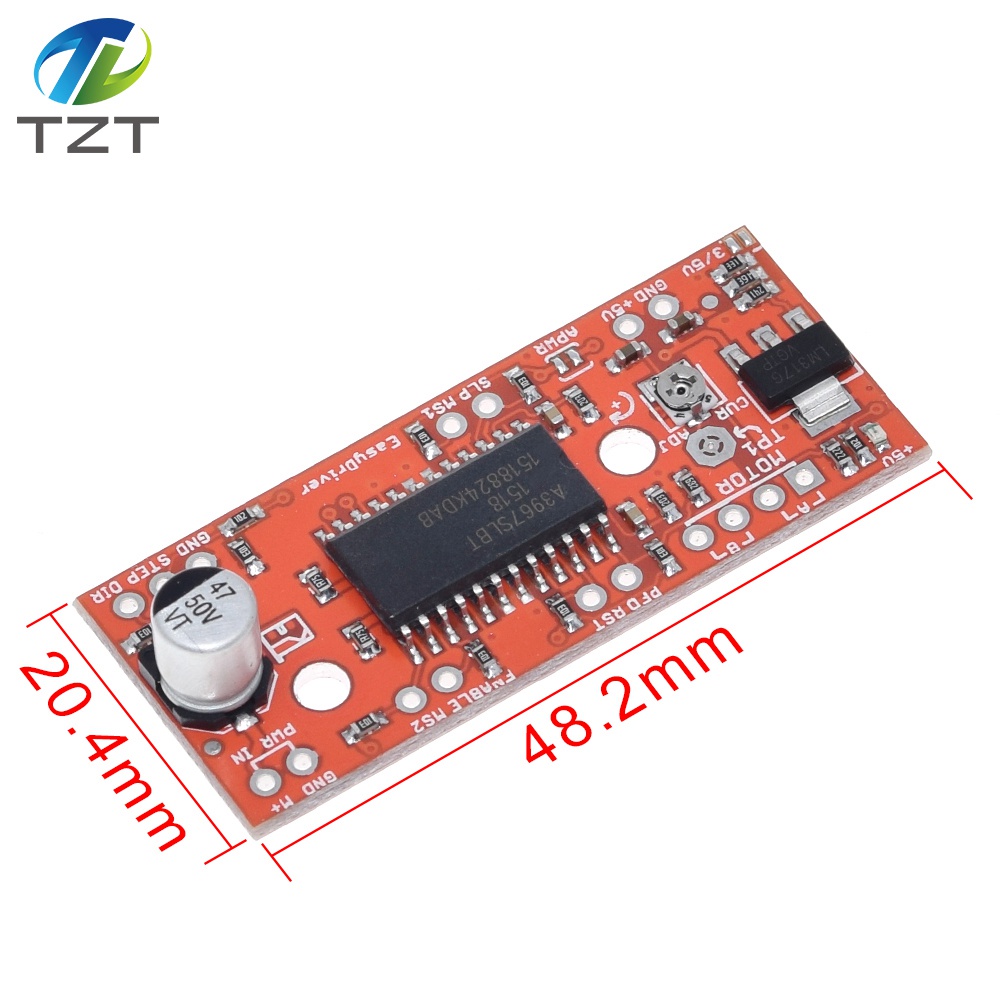

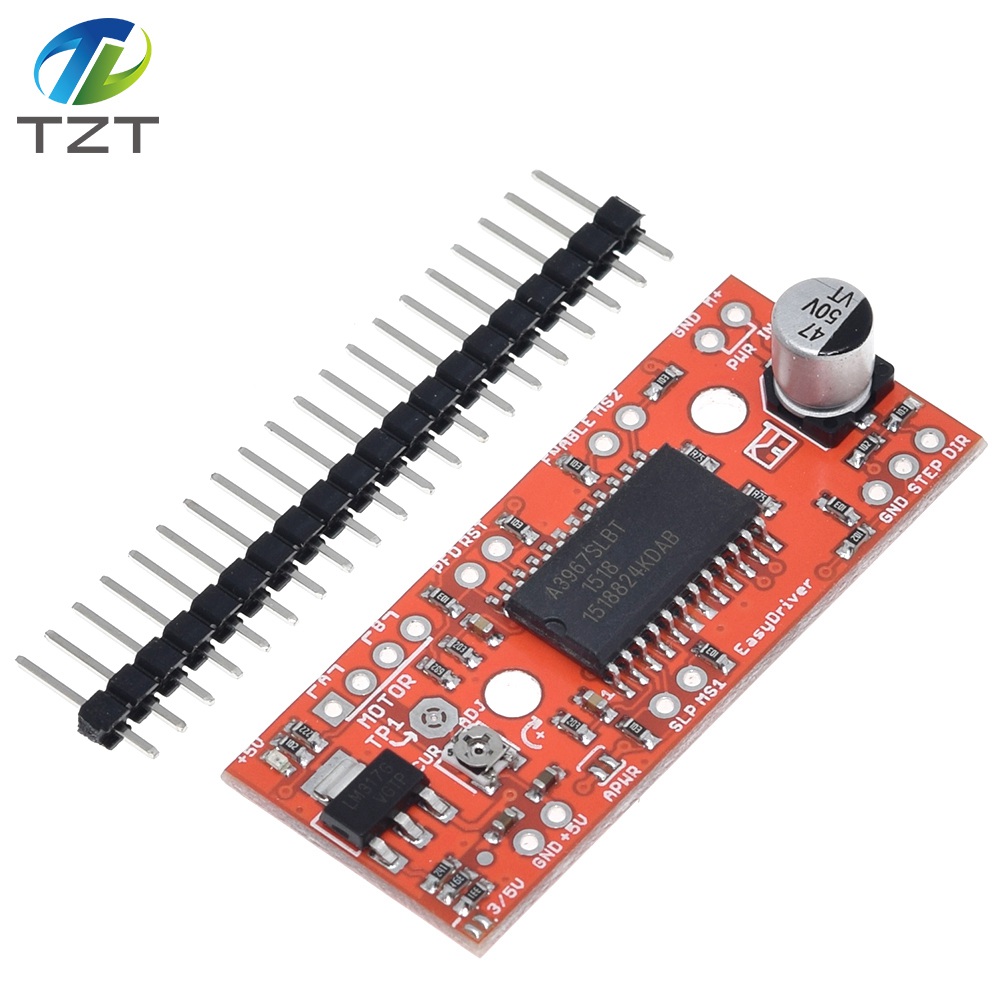

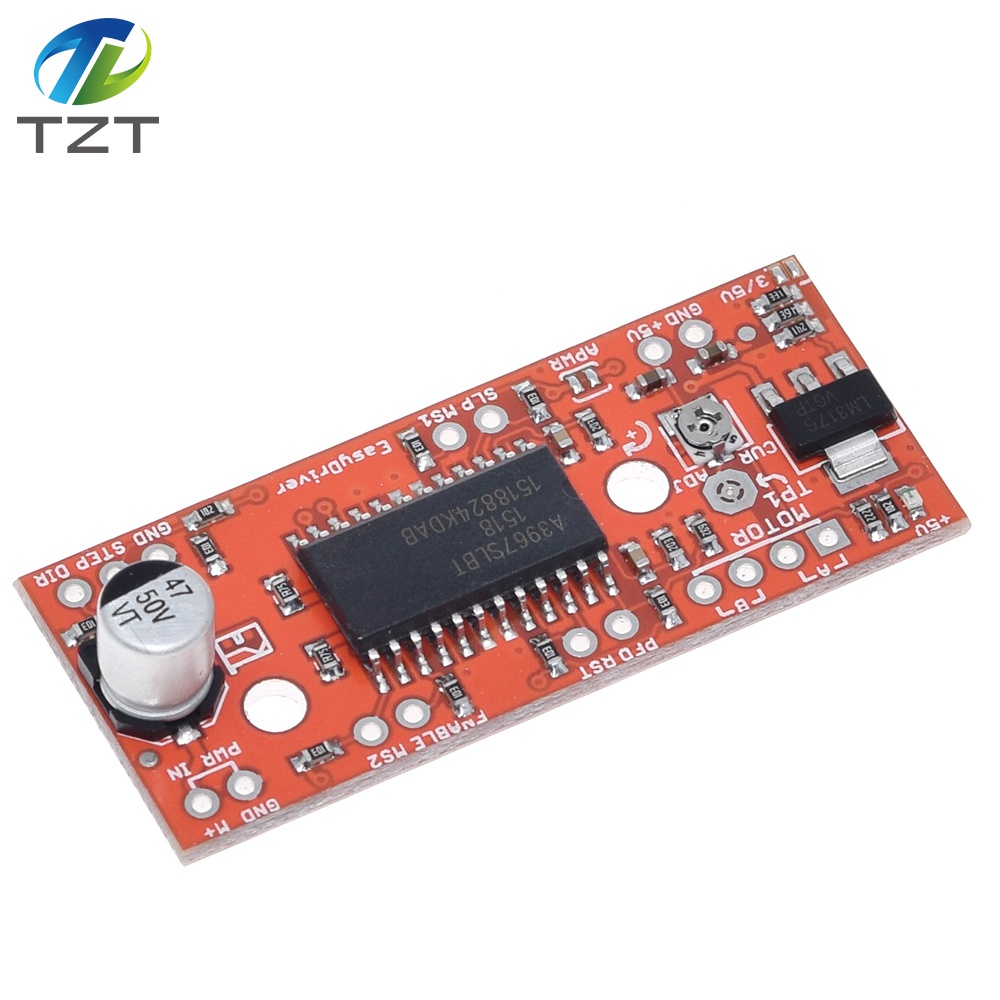

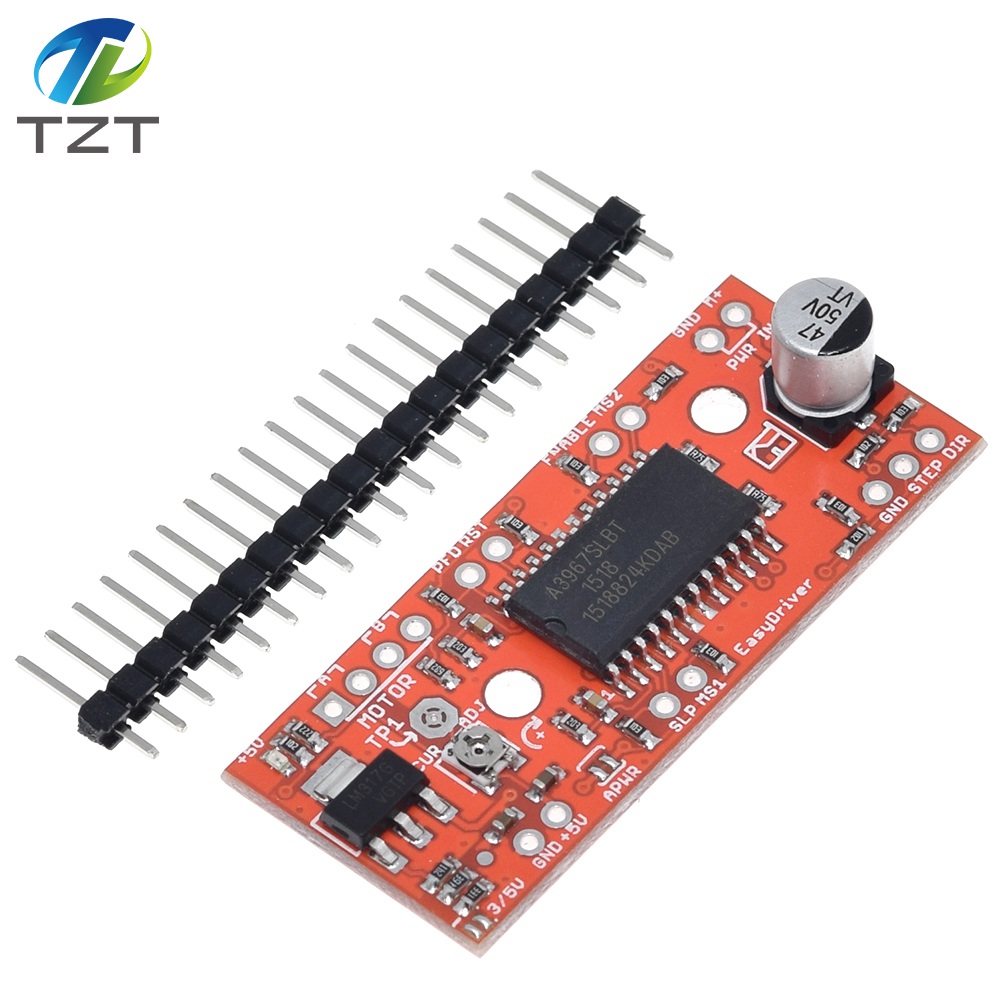

TZT A3967 EasyDriver Stepper Motor Driver V44 For Arduino Development Board 3D Printer A3967 Module

- Quantity:

Easy DriverExamples

Sample code and projects to get your stepperrunning!

Description:

Lotsof folks

buyEasyDriversorBigEasyDriversandthen get them to work just fine in their

project. But some don't,and so I thought it would be a good idea to write down

some simpleinstructions for getting your Easy Driver working as quickly

andeasily as possible.

Allof these

examples are going to be done with my Easy Driver and BigEasy Driver stepper

motor driver boards driving several differentrandom stepper motors I have lying

around the lab. I will begenerating the step and direction pulses

withanArduinoUNOandachipKITUNO32,although all of these examples should work with

any Arduino orArduino clone or Arduino compatible (like all

chipKITboards).

Anddon't

forget to read Dan Thompson'sexcellentEasyDriver tutorial blog postifyou want to

read more up on this stuff. Some great questionsanswered in the comments on that

blog post.

Note1:All

examples will work equally well with Easy Drivers or Big

EasyDrivers.

Note2:All

examples will work on Arduino as well as chipKIT boards (andsome will run much

better on chipKIT because of the PIC32speed)

Note3:All

examples show a barrel jack for power input - you need tosupply power to the

EasyDrivers somehow, but it doesn't need to bea barrel jack. You should have a

power supply that can output somevoltage between 5V and 30V, at 1 Amp or

more.

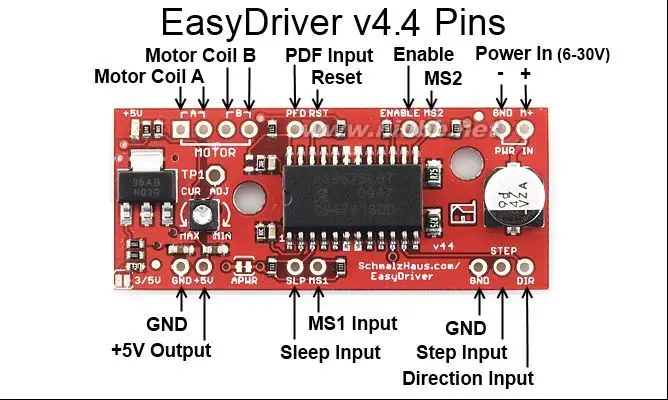

Example 1:Basic Arduino setup

Thisis the

most basic example you can have with an Arduino, an EasyDriver, and a stepper

motor. Connect the motor's four wires to theEasy Driver (note the proper coil

connections), connect a powersupply of 12V is to the Power In pins, and connect

the Arduino'sGND, pin 8 and pin 9 to the Easy Driver.

Thenload

this sketch and run it on your Arduino orchipKIT:

Itdoesn't

get much simpler than that. What is the code doing? It setsup pin 8 and 9 as

outputs. It sets them both low to begin with.Then in the main loop, it simply

toggles pin 9 high and low,waiting 1ms between toggles. We use pin 9 as the STEP

control andpin 8 as the DIRECTION control to the Easy

Driver.

Sincewe are

not pulling either MS1 or MS2 low on the Easy Driver low,the Easy Driver will

default to 1/8th microstep mode. That meansthat each time the "digitalWrite(9,

HIGH);" call is executed, thestepper motor will move 1/8th of a full step. So if

your motor is1.8 degrees per step, there will be 200 full steps per

revolution,or 1600 microsteps perrevolution.

Sohow fast

is this code going to run the stepper? Well, with the STEPsignal 1ms high and

1ms low, each complete pulse will take 2ms oftime. Since there are 1000ms in 1

second, then 1000/2 = 500microsteps/second.

Whatif we

wanted the motor to go slower? We change the delay(); linesto have longer

delays. If you use delay(10); for both, the you'llmove at 50

microsteps/second.

Whatif you

wanted the motor to go faster? We can't really delay forless than 1 ms, can we?

Yes, of course we can! We can change thedelay() calls to delayMicroseconds(100);

calls and then each delaywould be 100 microseconds (or us), so the motor would

be driven at5000 microsteps/second.

Now,one

thing you should play with is the current adjustment pot onyour Easy Driver. You

need a tiny little screw driver to turn it,and be sure not to force it too far

one way or the other (they'redelicate). Also, some Easy Drivers were built with

pots that haveno physical stops on them, so they spin around and around. As

yourun the above code, slowly turn the pot one way or the other.Depending upon

the type of motor you have (and its coil resistance)you may hear/feel no

difference as you spin the pot, or you maynotice quite a big

difference.

Example 2:Moving back and forth

Ifwe take Example 1, and simply change the sketch a little bit, wecan move a certain number of steps forward or backward. Likeso:

Nowusing this sketch, we move for 3600 steps in one direction, pausefor a bit, and move 3600 steps in the other direction. I'm sure youcan figure out how to make many different lengths of moves now. Andyou can change the delay between steps for each move to occur atseparate speeds.

Example 3:Using a pre-built library - AccelStepper

Onething the

above examples can't do well is handle multiple steppersfrom the same Arduino or

chipKIT. Also, acceleration anddeceleration are difficult as well. Other people

have run into thisproblem, and so now we have libraries that we can download

andinstall into the Arduino IDE or MPIDE to fix

theseproblems.

Downloadthe

zip file for the AccelStepper libraryfromthispage.Unzip the downloaded file, and

place the AccelStepper in to thelibraries folder in your Arduino install

directory. Note that forMPIDE (chipKIT) users, you need to copy the AccelStepper

folderinto both the libraries folder at the top level as well

as\hardware\pic32\libraries so that both the AVR and PIC32 sides canuse

it.

Usingthe

same hardware from Example 1, restart the IDE, and enter thefollowing

sketch:

Thiscode does basically the same thing as Example 2, but usingacceleration/deceleration via the AccelStepper library, and runningfor twice as many steps. (Thanks Mr. Duffy for pointing out thisimportant fact!) The reason it runs twice as many steps is becausewe do "pos = -pos" to keep things short and simple. This means thatit will run from 0 to 3600, then from 3600 to -3600 (which is 7200steps).

Example 4:Running multiple stepper motors

Oneof the

great things about the AccelStepper library is that you canrun as many stepper

motors as you want, at the same time, just bymaking more AccelStepper objects.

Now, if you try to run them toofast, the steps won't be smooth, so you have to

be careful not toload down the Arduino too much. The chipKIT does not have

thisproblem because it is so much faster than

theArduino.

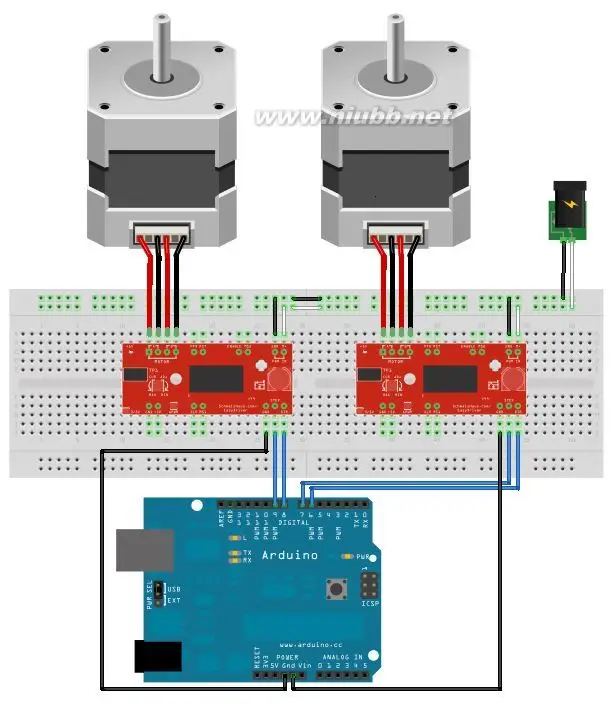

Inthis

diagram, we now have two Easy Drivers and two stepper motors.We just need 2 more

pins from the Arduino to add this secondmotor.

The code for

this example is shownbelow:

pos1 =-pos1;

Ifyou run

this code, you may find that the acceleration anddeceleration are not quite as

smooth as with a single motor (on anArduino - again, this problem doesn't occur

on chipKIT) - that isbecause our two maximum speeds (3000 and 1000) are pretty

high forthe ability of the processor to handle them. One solution is tomake your

max speeds lower, then switch from 1/8th microstepping to1/4, half, or full step

mode. If done right, you'll see the sameshaft rotation speeds, but with less CPU

load (because you aren'tgenerating as many steps per

second.)

Youcan see

that for this example, I just copied and pasted the codefrom Example 3 and made

two positions and two steppers. Thisexample code is very simple and not all that

useful, but you canstudy the existing examples from the AccelStepper library,

and readthe help pages on the different functions, and get good ideas aboutwhat

else you can do with your stepper control.

References:

Easy DriverPinout:

.png)

China (Mainland)

TUOZHANTENG electronic components Co., LTD

TUOZHANTENG electronic components Co., LTD

0755-82527072

0755-82527072

384834800@qq.com / 1244995775@qq.com

384834800@qq.com / 1244995775@qq.com

3013 Hongli Road, Shanghang Building 5F/511, Huaqiangbei , Futian , Shenzhen , Guangdong , China.

3013 Hongli Road, Shanghang Building 5F/511, Huaqiangbei , Futian , Shenzhen , Guangdong , China.

Hong Kong, China

TUOZHANTENG HK CO., LTD

TUOZHANTENG HK CO., LTD

emily384834800@gmail.com

emily384834800@gmail.com

Room 1103, Hang Seng Mongkok Building, 677 Nathan Road, Mongkok, Kowloon, Hong Kong

Room 1103, Hang Seng Mongkok Building, 677 Nathan Road, Mongkok, Kowloon, Hong Kong

WhatsApp +86 15920041318/ +86 17620404465

![]() WeChat +86 15920041318/ +86 17620404465

WeChat +86 15920041318/ +86 17620404465

Skype +86 15920041318

Telegram/ KakaoTalk :+86 15920041318

.png)

Recommended products

Recommended products

-

Tel

+86 17620404465 -

Wechat

-

Whatsapp